New Arrivals

Deals & Promotions

Patterson Private Brand

Patterson Office Supplies

Browse by Manufacturer

Custom Products & Services

3M, now Solventum

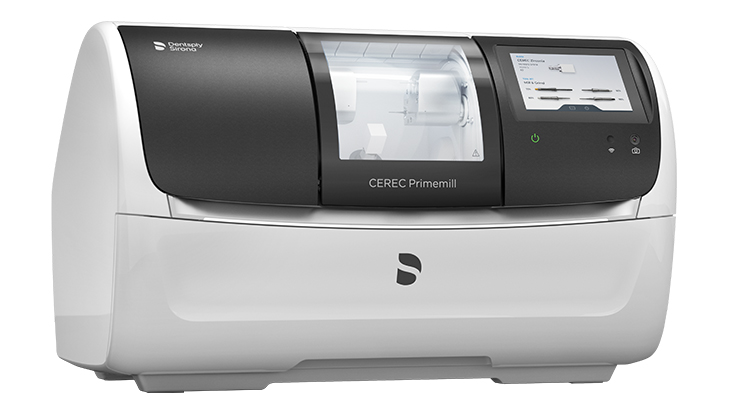

Dentsply Sirona

Kavo

My Catalog

All Merchandise Categories

Adhesive Agents, Materials & Accessories

Adhesive Agents, Materials & Accessories

Air/Water Syringes & Evacuation System Parts

Air/Water Syringes & Evacuation System Parts

Air/Water Syringe & Evacuator Assembly Replacement Parts

Air/Water Syringe & Evacuator Assembly Replacement Parts

CAD/CAM Blocks & Accessories

CAD/CAM Blocks & Accessories

CAD/CAM TiBase Kits, Drill Keys & Implant Scanning

CAD/CAM TiBase Kits & Abutment Screws

CAD/CAM Scan Posts

CAD/CAM Scanbodies

CAD/CAM Drill Key Sets

CAD/CAM Guide Block Kits

CAD/CAM Training Models & Model Fabrication Accessories

CAD/CAM Model Holders, Baseplates & Adapters

CAD/CAM Training & Calibration Models

CAD/CAM Model Fabrication Kits

Cotton & Paper Supplies

Cotton & Paper Supplies

Cotton Rolls, Pellets & Sponges

Absorbent Sponges

Cotton Pellet Dispensers

Cotton Pellets & Alternatives

Cotton Roll Dispensers & Holders

Cotton Rolls & Alternatives

Sponge Dispensers

Tongue Depressors

Sundry Jars & Holders

Crown & Bridge

Dispensing Syringes, Guns & Mixing Supplies

Dispensing Syringes, Guns & Mixing Supplies

Automatic Mixers & Vacuum Mixing Bowls

Automatic Mixing Unit Replacement Parts

Automatic Mixing Units

Mixer Mounts & Stands

Vacuum Mixing Bowls & Paddles

Dispensing Guns, Syringes & Applicators

Cotton-Tipped Applicators & Alternatives

Applicator Brushes, Handles & Tips

Dispensing & Irrigating Syringes

Dispensing Guns

Gun & Syringe Replacement Parts

Gun & Syringe Stands

Gun & Syringe Tips, Needles & Caps

Mixing & Intraoral Cartridge Tips

Pipettes & Droppers

Endodontics

Endodontics

Apex Locators & Obturation Systems

Obturators

Apex Locators, Pulp Testers & Accessories

Obturation Systems & Accessories

Endodontic Files, Reamers & Accessories

Endodontic Shaper

Endodontic Hand Files

Endodontic Rotary Files

Endodontic Reamers

Paste Fillers

Broaches

Endodontic Drills

Endodontic Pluggers & Spreaders

Endodontic Gauges & Rulers

Endodontic Stops

Endodontic Organizers & Accessories

Endodontic Miscellaneous

Finishing & Polishing

Front Office Products

Front Office Products

Appointment & Scheduling Products

Appointment Book Accessories

Dated Wirebound Appointment Books

Undated Wirebound Appointment Books

Standard Appointment Cards

Sticker Appointment Cards

Dated Looseleaf Sheets & Binders Appointment Books

Undated Looseleaf Sheets & Binders Appointment Books

Scheduling Systems

Billing Products & Daily Log

Miscellaneous Billing Products

Laser Checks

Manual Checks

Daily Log

ADA & HCFA/CMS Insurance Forms

One Write Accessories

One Write Products

Receipts and Deposit Slips

Laser Statements

Manual Statements

Superbills

Clinical Forms

Clinical Forms Miscellaneous

Clinical Form Sets

Complete Systems

Consent and Aftercare Forms

Exam and Specialty Forms

HIPAA Forms

Patient Information and Registration Forms

Prescription Blanks

Sign In Forms

Education Books & Software

Miscellaneous Books

Reference Books

Brochures and Patient Guides

CDT Coding Products

Educational Charts and Posters

Models and Teaching Guides

Software and Videos

Envelopes

Billing Envelopes

Drug Envelopes

Insurance Envelopes

Mailing Envelopes

Miscellaneous Envelopes

Nonwindow Envelopes

Window Envelopes

Filing & Accessories

Chart Dividers and Tabs

Fasteners and Accessories

File Envelopes

File Pockets

Filebacks

Filing Systems

Filing Units

End-Tab Folders

Top-Tab Folders

Outguides

Portable Storage Units

Labels

Biohazard Labels

Blank Color-Coded Labels

Collection and Billing Labels

Insurance Labels

Colwell/Patterson Jewel Tone Sytem Labels

Custom Labels

Chart and Exam Labels

G.B.S. Compatible System Labels

Jeter Compatible System Labels

Mailing Labels

Medication and Prescription Labels

Monthly Aging Labels

Name Labels

Numeric Labels

POS Compatible System Labels

Smead Alpha Z Compatible System Labels

Tab Compatible System Labels

Transcription Labels

Yearly Aging Labels

Office Supplies

Adding Machines, Calculators and Accessories

Batteries

Binders and Binder Accessories

Breakroom Equipment

Bulletin Boards and White Boards

Calendars and Planners

Cartridges, Toner and Ribbons

Cleaning and Janitorial Supplies

Computer Accessories

Correction Supplies

Label Makers and Labels

Labels and Badges

Markers and Highlighters

Paper and Notebooks

Pens and Pencils

Post-it Notes and Pads

Rubberbands, Clips and Tacks

Safes and Cash Handling Products

Scissors, Rulers and Trimmers

Shipping and Packaging Supplies

Stamps

Staplers and Paper Punches

Storage and Organization

Tape, Glue and Adhesives

Keurig Products and K-Cups (Coffee)

Telephone Accessories

Handpieces – Air & Electric

Handpieces – Air & Electric

Air & Electric Handpieces & Attachments

Air & Electric Handpieces

Air & Electric Handpiece Sets & Kits

Air & Electric Handpiece Attachments

Handpiece Lubrication & Maintenance

Handpiece Cleaner & Lubricant Caps & Nozzles

Handpiece Cleaners & Lubricants

Handpiece Maintenance System Adapters

Handpiece Maintenance System Oil Pads

Handpiece Maintenance Systems

Handpiece Cleaning Brushes & Wires

Handpiece Replacement Parts & Accessories

Handpiece Adapters

Handpiece Chucks

Handpiece Swivels & Couplers

Handpiece Cables

Handpiece Tubing

Handpiece Gaskets

Handpiece Index Rings

Handpiece O-Rings

Handpiece Engine Belts

Handpiece Torque Multipliers

Handpiece Turbines & Cartridges

Handpiece Bur Wrenches, Keys & Clamps

Handpiece End & Back Caps

Handpiece Holders & Mounting Brackets

Impression Material & Accessories

Infection Control

Infection Control

Barrier Protection

Barrier Film Dispensers

Chair Sleeves

Computer, AV & Pen Covers

Curing Light Sleeves

Headrest Covers

Light & Light Handle Covers

Syringe, Tubing & Handpiece Covers

Tray Covers

Universal Barrier Protection

X-Ray, Digital Sensor & Camera Covers

Personal Protective Equipment (PPE)

Face Masks

Face Shields

Finger Cots

Glove & Mask Dispensers

Gloves

Gowns

Patient Drapes

Protective Eyewear

Shoe Covers

Surgical Caps & Bouffants

Ear Plugs

Infection Control Kits

Autoclave Supplies

Autoclave Bag & Tubing Sealers

Autoclave Cleaners, Sterilants & Instrument Treatments

Autoclave Indicator Tape & Dispensers

Autoclave Pouches & Bags

Autoclave Replacement Parts

Autoclave Test Strips & Bio Monitors

Autoclave Trays, Baskets & Tray Liners

Autoclave Tubing

Autoclave Wrap

Biohazard & Medical Waste Supplies

Biohazard & Medical Waste Bags

Biohazard & Medical Waste Container Accessories

Biohazard & Specimen Transport Bags

Biohazard Waste & Sharps Containers

Hand Sanitizers, Soaps & Lotions

Hand Lotions

Hand Sanitizers

Hand Scrub Brushes

Hand Soaps

Soap & Sanitizer Dispenser Parts

Soap & Sanitizer Dispensers

Non-Disinfectant Cleaners, Supplies & Appliances

Fragrances & Air Fresheners

Non-Disinfectant Cleaners

Trash Bags & Liners

Sterilization & Disinfectant Cleaners

Cleaning Cloths, Pads & Sponges

Glutaraldehyde Test Strips

Sterilization Soaking Trays

Sterilizing & Disinfecting Solutions & Sprays

Surface Disinfectant Wipes

Instrument Management

Instrument Management

Instrument Labels & Identification

Instrument ID Labels & Markers

Instrument ID Rings

Instrument ID Tape

Instrument ID Tape Dispensers

Instruments

Instruments

Bracket Holders, Band Seaters & Accessories

Band Seaters & Pushers

Bite Blocks & Sticks

Bracket Height Gauges

Bracket Holders

Ligature Directors & Pickers

Burnishers, Carriers, Pluggers & Condensers

Amalgam Carrier Parts

Amalgam Carriers

Burnishers

Plugger & Condenser Parts

Pluggers & Condensers

Composite & Plastic Filling Instruments & Parts

Composite & Plastic Filling Instrument Kits

Composite & Plastic Filling Instrument Parts

Composite & Plastic Filling Instruments

Cord Packers & Gingival Retractors

Cord Packers

Esthetic Gauge Kits

Esthetic Gauge Replacement Parts

Esthetic Gauges

Gingival Protection Kit Tips

Gingival Protection Kits

Gingival Retractors

Elevators, Periosteals & Periotomes

Elevator & Periotome Kits

Elevators

Periotomes

Root Tip Picks

Sinus Lift Kits

Tunneling Instruments

Forceps, Pliers, Hemostats & Removers

Aligner Shaping & Cutting Instruments

Band & Bracket Remover Parts

Band & Bracket Removers

Crown Remover Kits

Crown Remover Tips & Parts

Crown Removers

Forceps

Hemostats

Needle Holders

Pliers

Pliers Inserts & Tips

Towel Clamps

Tweezers

Mirrors

Hand Mirrors

Mounted Overhead Mirrors

Mouth Mirror Handles

Mouth Mirror Heads

Mouth Mirror Accessories

Mouth Mirrors with Handles

Mouth Props, Cheek Retractors & Gags

Cheek & Lip Retractor Cushions

Cheek & Lip Retractors & Expanders

Mouth Gag Replacement Tips & Guards

Mouth Gags

Mouth Props

Placement Instruments

Cavity Liner Placement Instruments

Esthetic Placement Instrument Kits

Esthetic Placement Instrument Tips

Esthetic Placement Instruments

Membrane Placement Instruments

Scalers & Curettes

Curette Tips

Curettes

Flexible Scaler

Implant Scaler & Curette Kits

Implant Scaler & Curette Tips

Implant Scalers & Curettes

Scaler & Curette Handles

Scaler & Curette Kits

Scaler Tips

Scalers

Lab Products

Lab Products

Ceramics

Composite Indirect

Furnace Trays and Pillows

Porcelain

Porcelain Stains

Pressable Ceramics

Porcelain Pallets and Slabs

Ceramic Miscellaneous

Lab Instruments

Porcelain Brushes

Lab Waxing Instruments

Lab Instruments & Tools Miscellaneous

Measuring Gauges Lab Type

Lab Brushes

Lab Miscellaneous

Lab Alloy and Accessories

Plaster Traps and Accessories

Model Trimmer Wheels and Accessories

Saw Frames and Blades

Arbor Bands

Lathe Chucks

Articulators and Accessories

Casting Accessories

Burners and Torches

Dowel Pins

Separating Liquid and Foil

Splash Pans and Work Pans

Die Spacers and Lubricants

Lab Miscellaneous

3D Resins

Denture Material

Denture Base Material

Denture Repair Material

Denture Liner & Conditioner

Denture Material Miscellaneous

Flasks & Presses

Wax

Wax & Plastic Patterns and Molds

Plastic & Wax Sprues

Baseplate Wax

Boxing Wax

Utility Wax

Rope Wax

Casting Wax

Sticky Wax

Wax Shapes

Wax Bite Blocks

Wax Bite Wafers

Wax Miscellaneous

Vacuum Forming Machines & Material

Vacuum Forming Clear & Bleach Tray Material

Vacuum Forming Base Plate Material

Vacuum Forming Coping Material

Vacuum Forming Mouthguard Material

Vacuum Forming Temporary Splint Material

Vacuum Forming Tray Material

Vacuum Forming Machines

Vacuum Form Material Miscellaneous

Office Safety Products & Patient Monitoring

Office Safety Products & Patient Monitoring

Patient & Staff Monitoring Devices

Blood Pressure Monitors

Occupational Exposure Monitoring Badges

Oximeters

Stethoscopes

Vital Sign Measurement Tool Accessories

Resuscitation Devices

Bag Valve Mask Respirators

Defibrillators

Emergency Oxygen Units & Cylinders

Resuscitation Device Accessories

Pharmaceuticals

Preventive

Preventive

Oral Hygiene Products

Toys & Tooth Boxes

Fluoride Home Use

Dental Floss

Floss Dispensers

Floss Aids & Flossers

Interdental Cleaners

Toothbrushes

Specialty Toothbrushes

Brushes Power Assisted

Disclosing Agents

Mouthwash & Rinses

Tongue Cleaners

Toothpaste Regular

Toothpaste Prescription and Specialty

Restoratives/Cosmetic

Restoratives/Cosmetic

Curing Lights & Accessories

Curing Light Accessories

Curing Light Guides, Probes & Tips

Curing Light Shields

Curing Lights

Restorative/Cosmetic Instruments & Materials

Shade Matching Lights

Composite Universal

Composite Flowable

Composite Packable

Compomers

Glass Ionomer Restoratives

Composite Tints & Opaquers

Composite Glazes and Sealers

Core Build-Up

Caries Detector/Fracture Detectors

Shade Guides

Restoratives Miscellaneous

Articulating & Occlusal Indicators

Articulating Paper

Articulating Silk & Articulating Film

Occlusal Indicators

Articulating Paper Forceps

Articulating Miscellaneous

Retainer Bands & Wedges

Matrix Retainer

Matrix Bands Metal

Matrix Strips Plastic

Wedges

Matrix & Wedges Miscellaneous

Small Equipment

Surgical

Surgical

Anesthetics Syringes, Needles & Accessories

Anesthetic Needles

Anesthetic Syringe & Accessories

Needle Cappers

Anesthetics & Needles Miscellaneous

Training & Informational Materials

Training & Informational Materials

X-ray & Digital Imaging Supplies

X-ray & Digital Imaging Supplies

X-Ray Developing & Processing Supplies

Chairside Darkroom & Film Processor Replacement Parts

Darkroom Safelights & Filters

Developing Tank & Solution Accessories

Processor & Tank Cleaning Solutions

PSP Plate Guides & Transfer Boxes

X-Ray Cleaning Sheets & Wipes

X-Ray Developers & Fixers

X-Ray Film Carriers

X-Ray Film & Sensor Holders & Positioners

Intraoral Photography Mirrors

Panoramic X-Ray Bite Pieces & Chin Supports

Positioning Rings & Arms

X-Ray Cassettes

X-Ray Film & Digital Sensor Holder Kits

X-Ray Film & Digital Sensor Holders

X-Ray Screens

X-Ray Film, PSP Plates & Sensor Accessories

PSP Plates

X-Ray Duplicating Film

X-Ray Extraoral Film

X-Ray Film & Digital Sensor Accessories

X-Ray Intraoral Film